Hi-tech Shift

The MHOPHI platform enables you to progress towards being a digitally savvy organisation. We do this by digitising your manufacturing process.

Our platform strives to develop an intuitive overview of your production process by – categorisation and grouping of your manufactured products; rendering an online version of manufacturing operations; creating a digital flow of manufacturing process; building software based quality checks; and manifestation of production lines virtually.

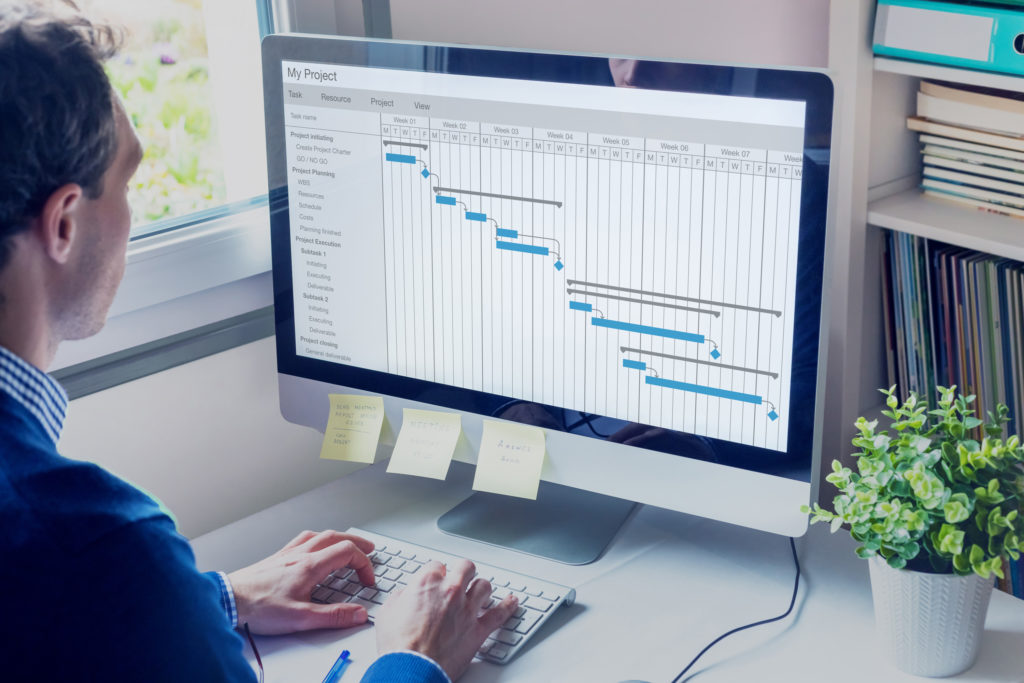

Meticulous Planning

MHOPHI platform provides you with a versatile playbook and host of features to effectively prepare for your production order.

We strive to significantly improve your production planning process by comparing orders against available capacity. You can also efficiently distribute products into production line, effectively allocate workstation to production lines, and manage contingencies for production lines. Additionally, you can schedule worker allocation based on production needs as well as adjust production plans in case of disruption.

Process regulation

Regardless of your preparedness and planning there are myriad challenges that crop up during production execution. MHOPHI platform provides multiple levers to digitally regulate the production flow .

You can create prioritisation rules to auto allocate jobs to workstations, and manage product capacity in production line. There is traffic signalling of load in production line along with provisions to manage clogs in a production line. At the same time there are an array of features to facilitate smart management of material resources. All of these features can be combined to smoothen many of the execution wrinkles.

Improving Bottomline

One of the topmost challenge of manufacturing industry to minimise defects and reduce waste. Fortunately, MHOPHI provides a lot of technology aids in this dimension.

User has the ability to combine products with similar manufacturing process into one production line. This helps not only in specialisation but also in process optimisation for the products. User can also track process deviations as well identify and manage all the risks and problems. Along with this users can also do tracking of defects plus in depth analysis of causality of defects.

Cost substantiation

Not all products in your portfolio have same lucrativeness. It is important to have realistic cost view of different manufactured products to maximise capacity allocation to profitable products.

MHOPHI allows you to track the production cost as well production time at each of the activity level. So you can pinpoint the production steps driving up your cost or delaying your execution. In addition, user can also track the variation in cost and time for each of the operations. Finally, all of these can be combined to develop an overall production cost and time view for the product which can be used for pricing decision and also in committing timelines to customer.